On-site machining has revolutionized the industrial maintenance sector by offering unprecedented convenience and efficiency. Techniques like line boring, bore repair, and bore welding are indispensable for restoring machinery to its optimal state. This article delves into several critical aspects of on-site machining, showcasing its significance and the various methods employed.

Line Boring

Read more about bore repair here.

Line boring involves enlarging a hole that has already been drilled or cast. This process is essential for ensuring perfect alignment in mechanical systems. Often used in large machinery, line boring provides a precise and effective way to align bearing bores and other cylindrical surfaces. The portability of on-site machinery makes it particularly beneficial for complex industrial setups, eliminating the need for dismantling hefty components.

Bore Repair

Bore repair is crucial for the maintenance of heavy-duty equipment. It’s a process designed to restore the structural integrity of worn or damaged bores. Methods like bore welding and xy milling are frequently employed for this purpose. The advancement in portable machinery has made it feasible to conduct these repairs directly on-site, substantially reducing downtime and costs.

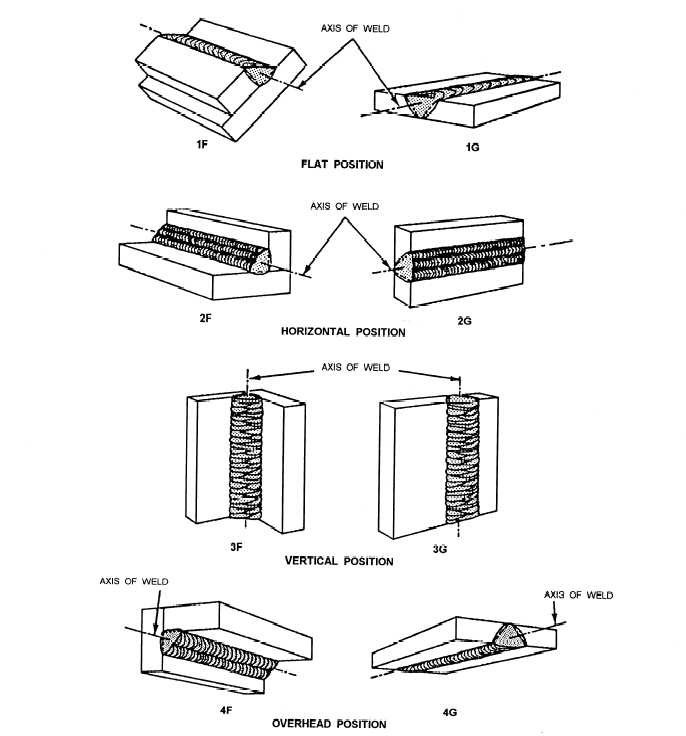

Bore Welding

Bore welding is a specialized technique used to fill in and rebuild worn-out bores. This process involves adding material to the bore surface through welding, followed by precision machining to restore the original dimensions. Bore welding is particularly beneficial when dealing with asymmetric wear patterns or critical component failures.

Slew Milling and XY Milling

Slew milling and xy milling are types of precision machining techniques aimed at restoring or enhancing the surface quality of machine components. Slew milling involves rotary cutting to remove material, while xy milling involves precise, linear cuts along the X and Y axes. Both methods are integral in achieving high-quality surface finishes and accurate dimensions.

Bush Install

Bush install is another essential on-site machining process. Bushings are critical components for reducing friction and wear between moving parts. Installing or replacing bushes on-site ensures that machinery operates smoothly and efficiently. The ability to conduct these installations without disassembly adds significant value to on-site machining services.

Face Welding

Face welding involves adding material to the face of a component, a technique often used to rebuild or repair surfaces subjected to excessive wear. This technique is utilized to enhance the lifespan and performance of industrial machinery parts. Like other on-site processes, face welding can be performed directly on the equipment, making it highly convenient and cost-effective.

Incorporating advanced on-site machining techniques like line boring, bore repair, and precision milling ensures that industrial operations remain seamless and efficient. The ability to carry out these tasks on-site significantly reduces downtime, enhances equipment lifespan, and optimizes performance.